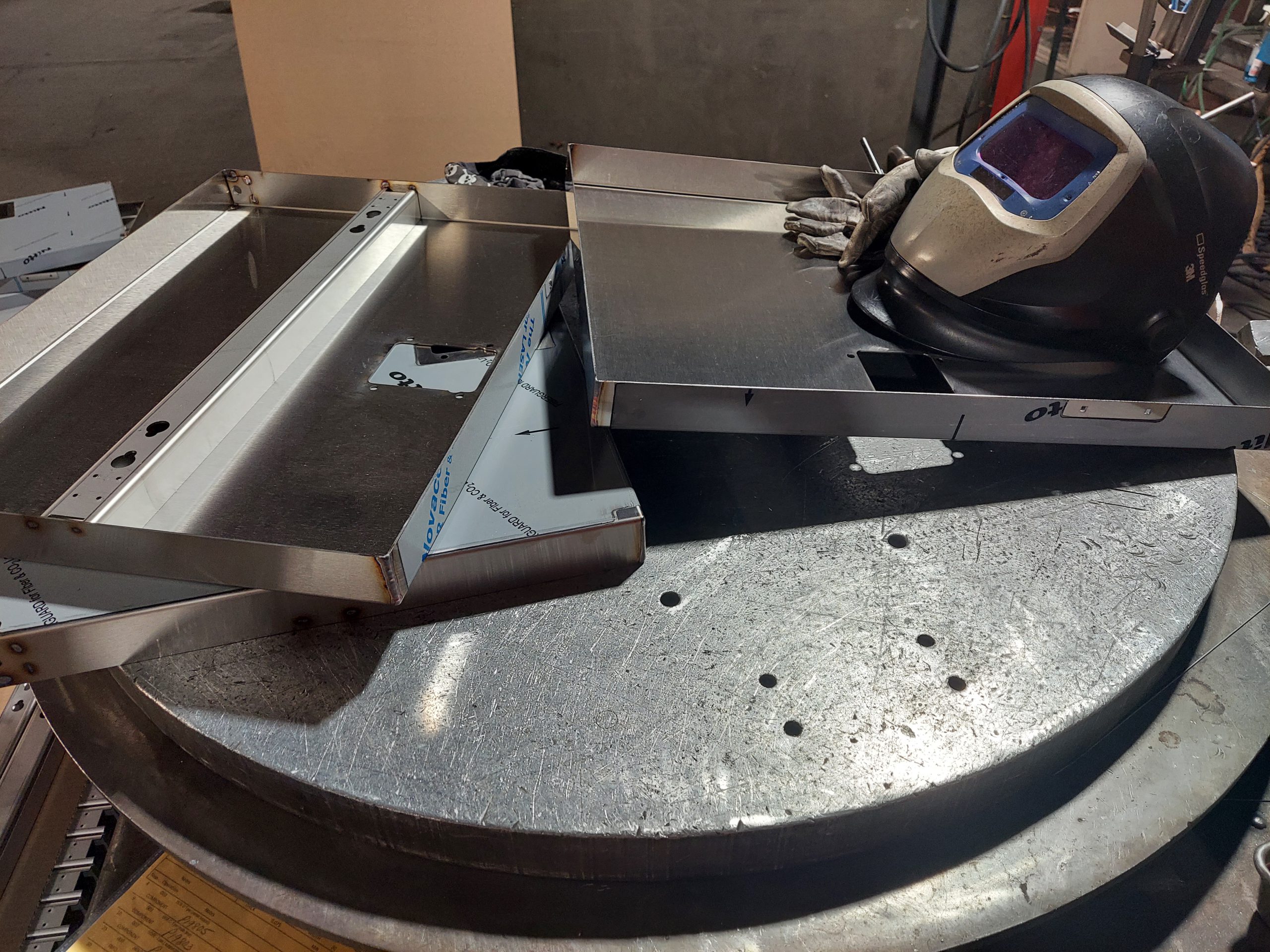

Dependable Stamping Company’s welding division, situated at 20850 St. Clair Avenue in Cleveland, Ohio, specializes in delivering high-quality welded assemblies with a focus on rapid production turnaround. Our welding division is equipped with state-of-the-art welding equipment capable of handling a wide range of welding processes and materials. This includes MIG welding, TIG welding, spot welding, and more. We excel in producing high-quality welded assemblies tailored to meet stringent standards and specifications.

Dependable Stamping also employs MIG welding, a process known for its efficiency and speed. MIG welding uses a consumable wire electrode and a shielding gas to create a strong, stable arc. This method is particularly effective for welding thicker materials and high-volume production runs.

Key Advantages of MIG Welding:

1. Efficiency: MIG welding is a faster process compared to TIG welding, making it well-suited for projects with high production demands. This efficiency does not compromise the quality of the welds.

2. Versatility: MIG welding is adaptable to a variety of metals and alloys, making it suitable for a broad range of stamping applications.

3. High Deposition Rates: MIG welding provides high deposition rates, allowing us to complete projects quickly without sacrificing the welds integrity.

We use TIG welding to achieve precision in our metal fabrication projects. TIG welding utilizes a tungsten electrode to create an arc that melts the base metals. The process is known for its ability to produce precise, and clean welds.

Key Advantages of TIG Welding:

1. Precision and Control: TIG welding allows welders to exercise precise control over the heat input, resulting in clean welds.

2. Versatility: TIG welding can be applied to a wide range of metals. This versatility makes it an excellent choice for diverse stamping projects.

3. Minimal Distortion: The focused heat input of TIG welding minimizes distortion and warping of the stamped metal, ensuring accuracy in the final product.

Robotic welding at Dependable Stamping Company represents a pinnacle of precision and efficiency in modern manufacturing. Our robotic welding division utilizes state-of-the-art robotic arms equipped with advanced sensors and programming capabilities. These robots are great at executing complex welding tasks with unmatched consistency and accuracy, ensuring high-quality welds across a variety of materials and part sizes, no matter of the quantity

Contact Us Today, or Call 216-486-5522