Fabricating Equipment Information

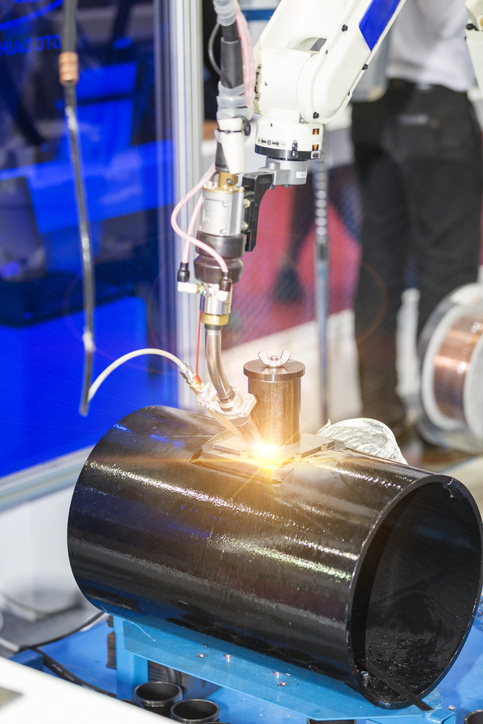

Laser Cutting:

Laser cutting is known to be one of the most stable and accurate cutting processes. There is never a need for secondary grinding, and it can reach places where other welding procedures would be difficult to reach. Laser cutting always results in the highest quality finish.

We offer laser cutting on the following materials:

- Stainless steel: all grades and finishes - 201,430,316 and 321, and thicknesses of 010-500.

- Carbon steel:020-750 thick.

Call us about any special requests.

We have the following finishes available:

- 2b

- #4

- ROF

- PVC coated

- Special finishes available upon request.

Quotes on all laser cutting jobs are returned within 1-2 days.

CNC Punching

Our CNC Punching machines have exceptional forming and bending capabilities. We can accommodate 48”x96” steel and stainless sheet sizes. For other metals call us. Turnaround time for a standard job is 1-2 weeks.

CNC Press Brake Forming

This is essential for bending sheet metal panels. This application is mainly used for commercial and industry. Our machine tonnage ranges are up to 175 tons and foot bed lengths of 10 feet long beds.

We produce components for after-market truck parts, commercial oven parts and hydraulic tanks.

MIG

MIG stands for Metal Inert Gas. It is an arc welding process in which a spark is created in the welding gun by using a continuously moving wire electrode. The spark melts the metal to form the weld and joins the two base metals together. In order to protect the weld pool from contamination, a shielding gas is sent through the welding gun. This is the preferred process for aluminum, stainless steel, and steel in every thickness ranging from 26-guage steel metal to heavy structural plates.

Because it can run continuously for long periods of time it is very cost effective and extremely diverse.

TIG

TIG stands for Tungsten Inert Gas. Like MIG, this is also an arc welding process. TIG produces the weld with a non-consumable tungsten electrode. It can be used to meld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze, and gold. It is the most accurate of all welding machines, and is a very clean aesthetic weld that is free of splatter.

Steel Fabrication Instant Fasteners

Steel Fabrication Instant Fasteners: We carry three fasteners. Pem Fasteners, Spot Welded Fasteners, and Nelson Stud Welder Fasteners which are used for special welding processes.

Tapping

Tapping is a high speed process used for cutting a thread inside a hole. Its advantage is the depth of holes it can produce and the hardness of the metals that it can penetrate.

Powder Coat (painting) Plating

Powder coat (painting) plating: Although it looks like paint, powder coating is more like a shield of armor.

We use two processes (1) thermosetting which involves adding chemicals to react to the powder, and (2) thermoplastics which simply melts and flows into the coating.

In either process there are five obvious benefits:

1. The result of powder coating is a dense, durable finish which will outlive any paint job.

2. Powder coating is quick and easy.

3. Powder coating can include innumerable custom colors.

4. Because it produces very few volatile organic compounds, powder coating is considered safe for the environment.

5. Powder coating produces the most even surface there is because it is sprayed on and has no drips.